Double Injection Molding, now and again known as 2 material 2 shot embellishment or 2K forming, is an inventive assembling process used to deliver entangled shaped parts from two distinct materials. Through a very particular and mechanized procedure, we cautiously control the infusion of various materials, including two various types of pitch, into a solitary, multi-chambered shape.

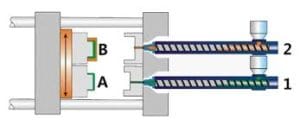

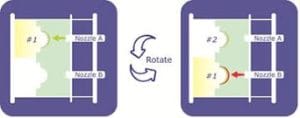

Double Injection in performed on one machine that is customized to perform two infusions in a single cycle. In the principal cycle, a spout infuses plastic into shape. The form is then naturally pivoted and an alternate kind of plastic is infused into the shape from a second spout.

Twofold Injection Molding improves co-polymerization of hard and delicate materials to make ground-breaking sub-atomic bond. The outcome is a solitary part with creation and highlight points of interest. It tends to be utilized for an assortment of item structures overall ventures. It additionally takes into consideration shaping utilizing clear plastics, shaded designs and snappy completions which improves your item usefulness and commercial centre esteem.

► Double Injection Injection favourable circumstances include:

► Lower unit cost

► Improved part uprightness

► Multi-material effectiveness

► Higher-quality plastic part creation

► Decreased taking care of and optionally get together

► Decreases cost and waste related with gathering surrenders

► Upgraded material and restorative item includes