Are you looking for plastic chair mould for your market? please contact us, we are professional custom plastic mould manufacturing company in China, we offer custom plastic chair mould bease on your idea, sample, 2D or 3D drawing. below are some steps to guide you how to start make plastic chair mold.

How to develop new plastic chair mould? How to order a plastic chair mould? How to make chair molding ?

Welcome to Olayer mold here and we will offer you most professional information for plastic chair design and plastic chair moulds with complete line for your building of new plastic chair mould facotry.

To start your plastic chair mould facotry, you must get start with injection machine, plastic chair mould, plastic chair moulding technology as well as a good plastic chair design.There are many types of chairs can be found in our life.They include Arm chair, Armless chair, Baby chair, Art chair, Office chair, Public chair, Bus chair, Beach chair, Folding chair, Dining chair, Leisure chair.

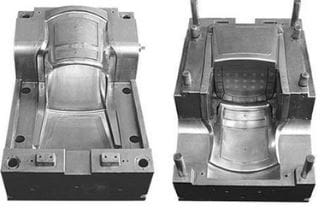

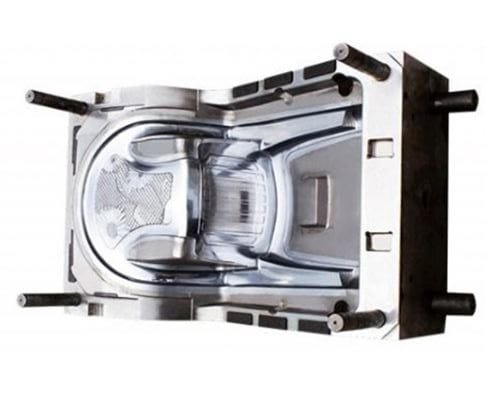

plastic chair mold

plastic chair mould

plastic chair moulding

Come with your target plastic chair mould idea, choose the plastic chair type. In order to make your plastic chair mold more competitive in the market, we can make good plastic chair moulds for your choose base on your corrent idea, such as gas assistant plastic chair moulds, water assistant plastic chair moulds, armless plastic chair moulds with steel legs.

When you have your plastic chair mould idea, the next step is how to make a profitable plastic chair mould. A good plastic chair mould, has high speed running with very fast cycle time. This including a good design inside the plastic chair mould cooling system, a smooth movement in plastic chair mould sliders and ejection systems, opending system. Also a good thickness arrangement in the plastic chair mould, a good runner system for flow the plastic material into the plastic chair mould molding cavity area. Good polish surface for fast material flow and so on.

The 3rd step is that you choose a very good injection machine for plastic chair mould production. Usually, the plastic chair mould can choose 780 injection machine size. To choose the good injection machine model for produce your plastic chair mould can save your cost, such as servo motor system injection machine for plastic chair mould, it can save oil, save energy and save power. During the plastic chair mould cooling time, machine do not act. This can save a lot of cost for you in the long run.

Olayer mold can offer you fine solution for plastic chair mould/molding service. We get auxillary machines for the injection plastic chair mould line, gas assistant equipment for plastic chair mould, interchangeable plastic chair mould design and patent chair shaping design for your new invented chair shape.

Welcome your enqiury for plastic chair mould factory building and world latest technology for improving your chair facotry profit in short time. We will offer you the high quality of plastic chair moulds for you to win your market. contact us now to get price.