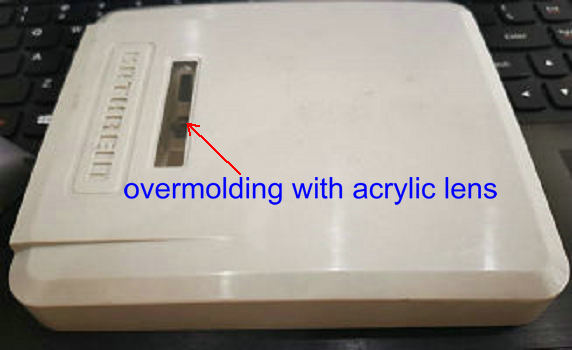

If you have never heard of the word “overmolding“, it can sound like a bad, quite nasty thing: it sounds like a big, overgrown amount of mold. However that is not what the word means at all, and engineers and mechanics will probably be rather familiar with the word: overmolding is a process that is used to create a part of an object by using two different materials it is similar to two shot molding but different. Usually, the first part (called “the substrate”) is covered by the secondary materials (called “the overmold materials”) during the process of making the object. Both materials can be anything: rubber, plastic, metal… but usually, the first one (called substrate) is metal, and the second one (called the overmold material) is plastic.

The overmolding process is used for a number of really varied reasons that can change according to the process. Plenty of different household items that you use on the daily use this process, for example, toothbrushes, cordless drills, screwdrivers or shampoo bottles; and the reasons to use this process are plenty varied: for aesthetics, to protect the user’s hands and allow for a better grip, to improve the resistance and the quality of the object…

This technique has, of course, plenty of different pros and cons. For example, among the pros we can find that using this technique greatly improves the beauty of our products, allows for our products to have a better quality and be more resistant and durable, it allows for better grip and more safety in the case of metal tools that are going to be used for repairs next to electrical areas, it can be used to provide a rigid part with flexible, moldable areas or to encase one part inside of another without a need for adhesives, it can be used to make the manufacturing process faster, cheaper and more efficient…

However, overmolding can also have some cons. If you are producing a tool that could entirely be made out of metal, having some pieces made out of plastic heightened the chances of this pieces breaking or falling off, and by having to introduce new materials in your production line you might end up having to pay more and needing more time to produce them which can be a significant loss for your business. This technique might be hit or miss depending on how much money and time you are willing to invest in producing your products.

If you are looking to introduce this kind of technique in the production and manufacturing of your projects, it is best to use a professional: it can be the thing that makes or sinks you business and if you are starting out a small enterprise, trying to do everything by yourself will cost you way more money than it will save you; so be smart and business-savvy and find yourself a professional that can do it for you: it will save you money in the long run and it will help you create high-quality products that you will be proud to sell.

If you are looking for overmolding service from China, we are one of the best partners for you, we are a mold manufacturer China, offer custom plastic mold to the world, if you want to know more info about over-molding, you are welcome to another overmolding page, that will help you more and hope you could find your solution.